Riyadh System’s

RFID Laundry Management System

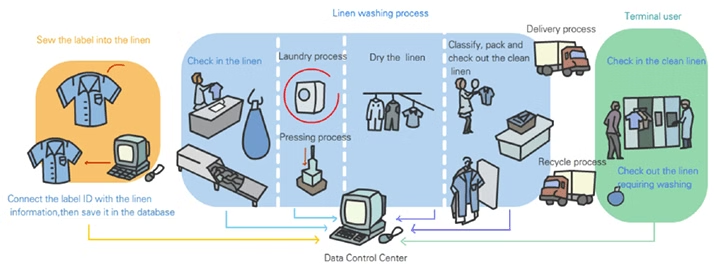

Hospitals, hotels, industrial laundry facilities, or any company with multiple types of textiles have a sorting process for laundering. With Riyadh System's IoT Gateway, integrated with Desktop and cloud and RFID based LMS (Laundry Management System) determines what type of textile is being read and directs it to the proper area or machine. The software’s findings can be displayed on a screen so that a person can immediately direct the textile or linen to its next destination.

Efficiency

Efficient identification of linen and the ability to track and trace pieces throughout the process line and even enroute to and from the customers could be said to be at the heart of effective laundry management.

The textile, linen rental, and process industry has undergone high modernization in recent years and is more technologically advanced than ever before. Radio-frequency identification (RFID) technology is one of the latest advancements that is revolutionizing the sector and at the Riyadh System RFID solutions we offer our customers to take all the advantage of the fast and error-free processes through RFID Laundry Management System.

Linen base industry units have also recognized that the use of RFID is going to be an increasing trend for their laundry customers and are promoting services that they can offer to assist.

Quality Control

Quality control can also reach higher levels of accuracy because the laundry is able to analyze and monitor the journey of individual items. This means it can identify when an item is reaching the end of its lifespan, so it can be replaced immediately. This results in fewer items being rejected manually during the laundry process and provides hotels with a further increased level of service efficiency. Control over stock allows laundries to understand who their customers are and how they are using linen, and at the same time, customers want a clearer view of the service they receive.

Error Free bulk Inventory

Instead of scanning every individual item by hand, assorted linens can be scanned in one go via Riyadh System’s RFID Handy or by RFID enabled conveyor belt scanner before being scanned again once sorted into their various item categories. The items are scanned at the collection point via UHF Handy scanner uploading data over WiFi or 4G/5G network to inform the processing centre of its collection and category count to be ready for the next action. Once it arrives at the laundry, stock counts are taken in linen rooms using RFID bulk counters (handheld for fixed scanners) with all the information recorded then updated in the Riyadh System RFID Cloud.

This dramatically reduces the number of hours spent manually sorting linen and offers a far more reliable counting and tracking method for stock. The same way it can be recounted for the delivery and collect acknowledgment from customers.

This simple and transparent RFID based process, allows customers to be in complete control of their linen stock and can even inform the laundry when a new delivery is required. This can be done by simply scanning clean stock stored in linen rooms by their own staff wearning RFID Wristband to track their performance and to create an inventory that is uploaded to the cloud and forms the basis for the items that will be ordered the next day. Being able to monitor stock (available and in-processing) levels so quickly and efficiently benefits both sides of the customer and linen processor. One of the main advantages for the customer is that they don’t have to manually count and sort the laundry which significantly reduces labour costs and increases accuracy.